Why Choose Seconline?

- When you buy a sliding door with Seconline you are buying a quality Australian made product at the best possible price, constructed to your exact specifications.

- Seconline sliding screen doors are delivered direct to your home or business fully assembled and ready to install.

- Our simple, comprehensive measure and installation video guides are compiled by our qualified installers to provide you with the best possible advice. We're also online to chat if you need us!

- Improve the value of your home and the security of your loved ones

Which Sliding Door is right for you?

- START BUILDING

TOUGH Sliding Security Door

From$712 - Available in 16 colours

- Available in Western Red Cedar effect

- STRENGTH

- Security

- Airflow

- Visibility

- STRENGTH

- 316 Marine grade stainless steel mesh

- T6 extruded aluminium frame

- Exceeds Australian Standard

- BAL 40 fire rating

- Austral lock and cylinder fitted

- Triple locking upgrade available

- Top and bottom rollers

- Frame interlock and rivets included

- Non-Standard powder coating option

- View full tech specs

- START BUILDING

LOW-VIS Sliding Security Door

From$641.99 - Available in 16 colours

- STRENGTH

- Security

- Airflow

- Visibility

- STRENGTH

- Restricted vision mesh for privacy

- Corrosion resistant mesh and frame

- Compliant with Australia standards

- Austral lock and cylinder fitted

- Triple locking upgrade available

- Top and bottom rollers

- Frame interlock and rivets included

- Additional interlocks and tracking available for purchase

- View full tech specs

- START BUILDING

PERF Sliding Security Door

From$617.99 - Available in 16 colours

- STRENGTH

- Security

- Airflow

- Visibility

- STRENGTH

- Corrosion resistant mesh and frame

- Unyeilding security for large spaces

- Austral lock and cylinder fitted

- Triple locking upgrade available

- Top and bottom rollers

- Frame interlock and rivets included

- Meets Australian Standards AS5039

- Additional interlocks and tracking available for purchase

- View full tech specs

- START BUILDING

Diamond+ Fly Sliding Door

From$447.99 - Available in 16 colours

- STRENGTH

- Security

- Airflow

- Visibility

- STRENGTH

- Tempered aluminium diamond grille

- Four mesh upgrade options

- Available in 16 standard colours

- Austral lock and cylinder fitted

- Triple locking upgrade available

- Cost effective barrier screening

- Top and bottom rollers

- Side bug seal fitted

- Tracking available for purchase

- View full tech specs

- START BUILDING

FLY Sliding Screen Door Fibreglass Mesh

From$383.99 - Available in 16 colours

- STRENGTH

- Security

- Airflow

- Visibility

- STRENGTH

- Horizontal support bar in centre

- Charcoal fibreglass fly mesh

- Fully assembled ready to install

- Austral lock and cylinder fitted

- Side bug seal fitted

- Top and bottom rollers

- Option for magnetic latch instead of lock

- View full tech specs

- START BUILDING

FLY Sliding Screen Door Midge Mesh

From$418.99 - Available in 16 colours

- STRENGTH

- Security

- Airflow

- Visibility

- STRENGTH

- Midge mesh 20 x 20 stands per inch

- Horizontal support bar in centre

- Fully assembled ready to install

- Austral lock and cylinder fitted

- Side bug seal fitted

- Top and bottom rollers

- Option for magnetic latch instead of lock

- View full tech specs

- START BUILDING

FLY Sliding Screen Door Paw Proof Mesh

From$433.99 - Available in 16 colours

- STRENGTH

- Security

- Airflow

- Visibility

- STRENGTH

- Heavy gauge polyester material

- Horizontal support bar in centre

- Austral lock and cylinder fitted

- Fully assembled and ready to install

- Side bug seal fitted

- Top and bottom rollers

- Option for magnetic latch instead of lock

- View full tech specs

- START BUILDING

FLY Sliding Screen Door - Fire Rated Fly Screen Mesh

From$433.99 - Available in 16 colours

- STRENGTH

- Security

- Airflow

- Visibility

- STRENGTH

- Black 316 Stainless Steel fly mesh

- BAL 40 compliant for fire rating

- Fire and heat resistant mesh

- Horizontal support bar in centre

- Side bug seal fitted

- Top and bottom rollers

- Austral lock and cylinder fitted

- Option for magnetic latch instead of lock

- View full tech specs

How it works

- Choose your product

Select from our range of hinged doors, sliding doors & window screens

- Measure your space

Use our comprehensive video guides to accurately measure up or send us inquiry for installation

- Build your product

Use our custom built Product Builder to select your mesh type, colour and additional items

- We build your screens

Custom manufactured by our craftsmen in Australia

- Shipped Australia wide

We offer prompt, safe and affordable delivery

- Install your screen

Use our guides to install your product yourself or send us an inquiry for installation

Security you can trust

With Seconline you are buying a quality Australian made product constructed to your exact specifications, shipped direct to your door.

Seconline is a trusted Australian owned company with over 25 years experience making and selling security screening products

Simple, comprehensive measure and installation video guides

Buying online with Seconline saves you hundreds without compromising on quality

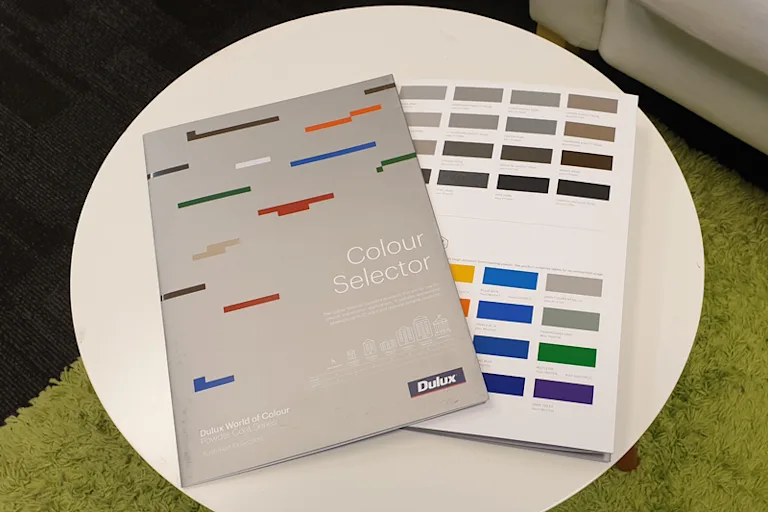

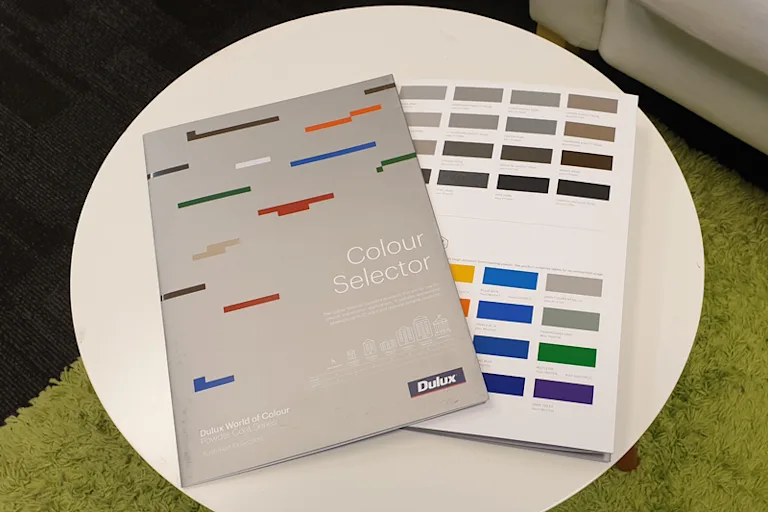

Finishing touches to suit your style

We have 17 standard colours across all our ranges and a large selection of accessories and hardware to improve the function and practicality of your security screening products.

Learn more about colour selectionPremium finishes

Our TOUGH security screen doors are available in a premium Western Red Cedar timber effect finish, or, if you still can't find the colour you're after, our custom colour options ensure you'll always find the perfect finish for your screen.

Customer reviews

We ordered new front and rear screen doors. They arrived sooner than expected and I am wrapped with the quality. Installed them quickly and easily without needing to leave home.

I was extremely happy with the two screen doors we received. Such an easy process from very easy instructions all the way through on their website from measuring to instillation. As long as you can hold a tape measure and handle a power drill you to will find it an easy experience. Delivery was prompt even in these crazy times, the doors turned up well packaged. Thank you Seconline!

Such a great product and whilst I was thinking my door would have a bar across the middle which I wasn’t super keen about, only to find no bar and looks amazing. Super great service and product - have added some pics to show how good it looks.